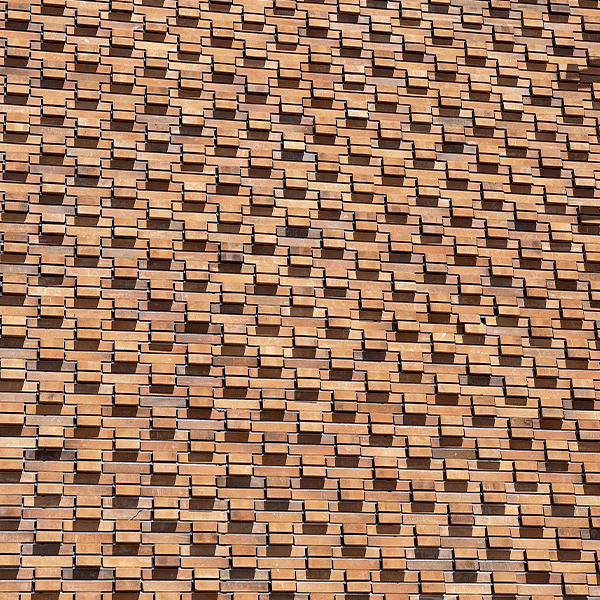

in the execution of the facade in a dry manner due to the lack of use of mortar; Grout or glue and conflict of all facade components with its specific connections, which is the result of not being arranged, destruction or falling of facade components after a long period of time. Also, this method of performing the facade has reduced the weight a lot. In this regard, much less load is brought to the building and also because of the engineering design and calculations based on the existing regulations regarding the implementation of dry facades and the construction of the facade according to the designed details, very high resistance to tension. caused by earthquakes.

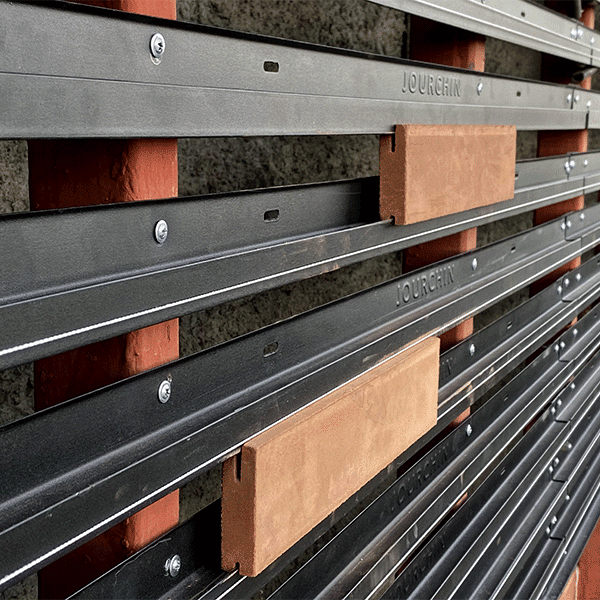

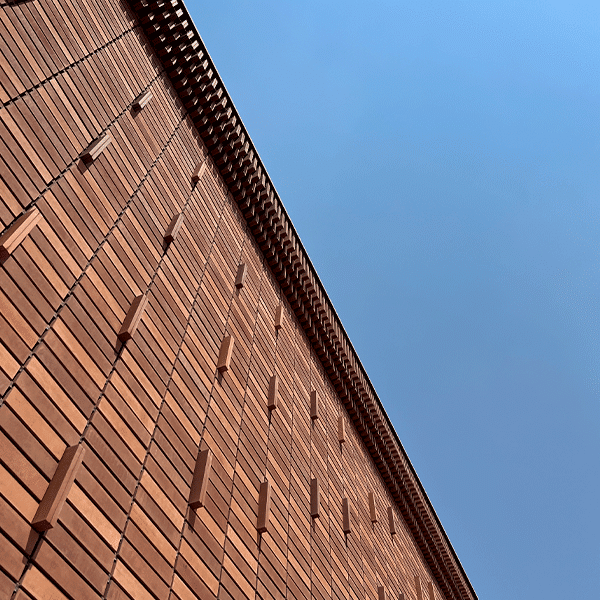

Dry brick facade system using the Jourchin rail method

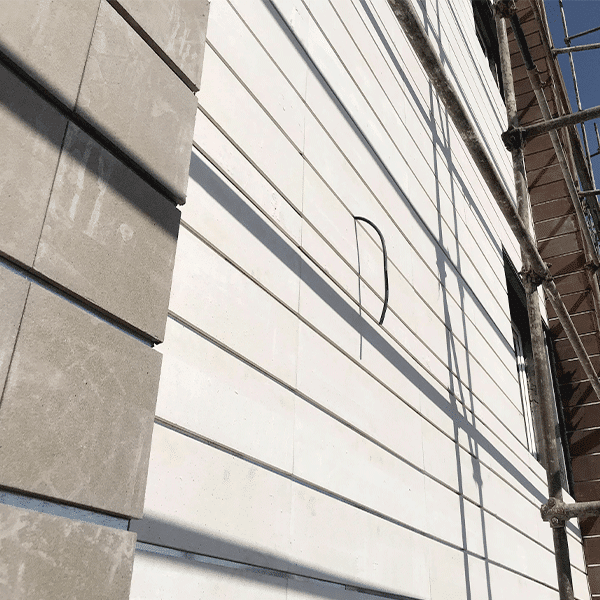

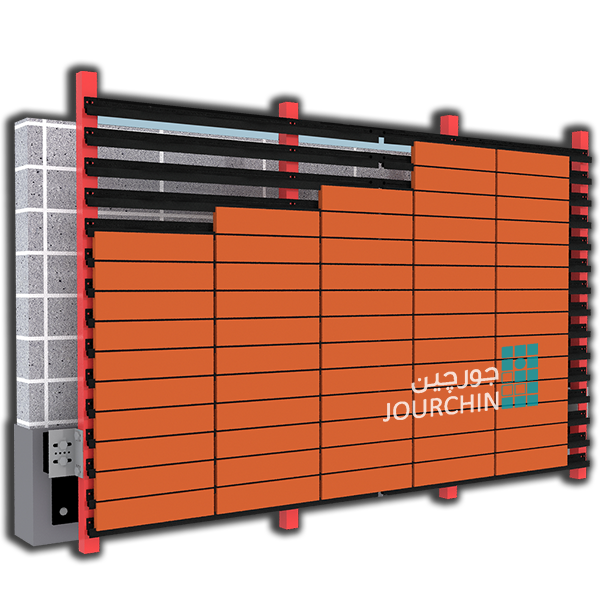

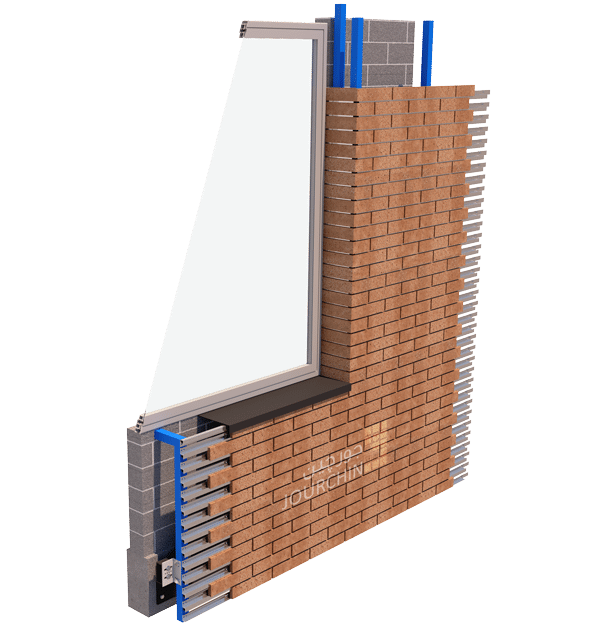

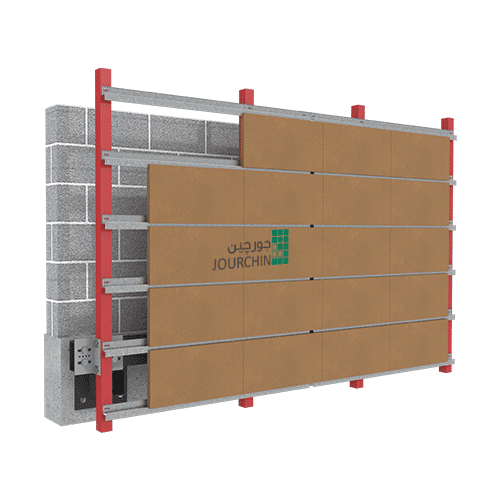

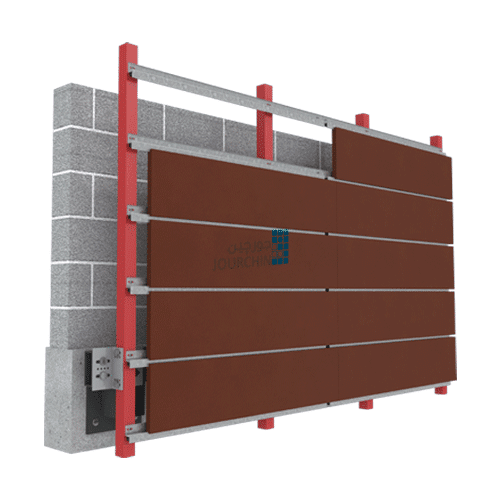

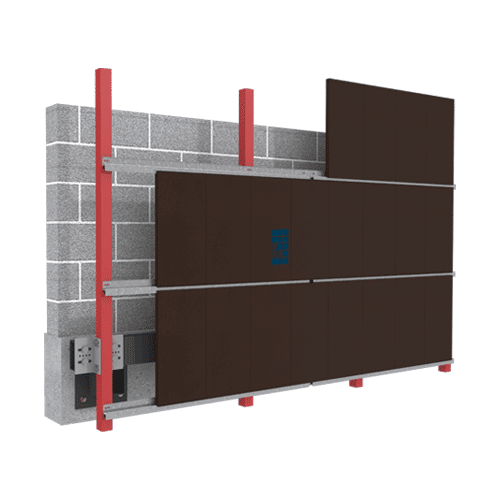

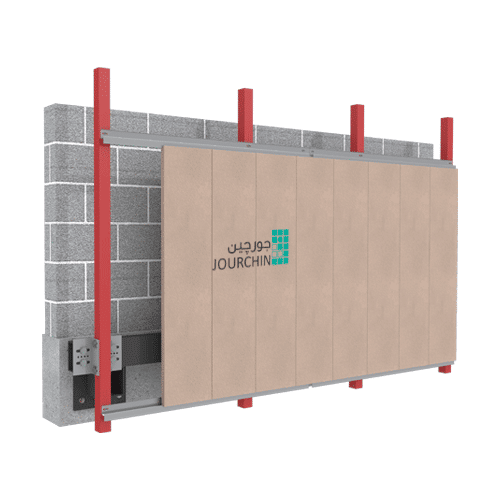

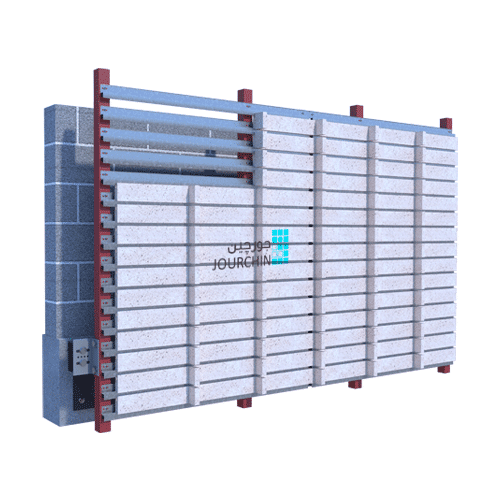

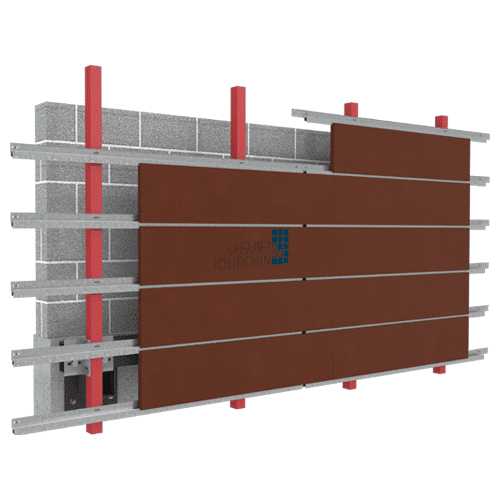

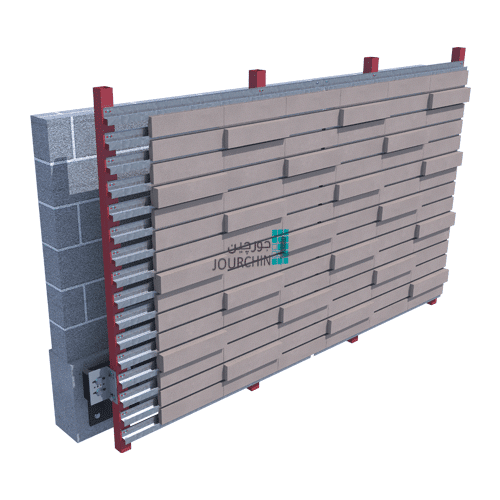

This method of implementing the facade system is self-static and mechanical and is done without using mortar and grout in a completely dry porcelain method. Dry brick facade has different stages and layers. The first layer is the supporting structure of the facade, the second layer is the supporting joints for bricks, and at the end, the desired facade brick is installed for the final covering of the facade.

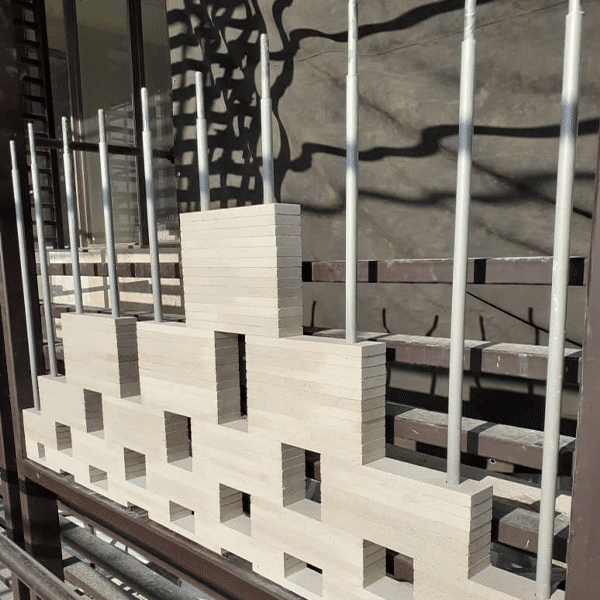

The implementation steps of the constituent components of Jourchin's dry brick facade

Components of Jourchin dry brick facade

Jourchin dry brick facade

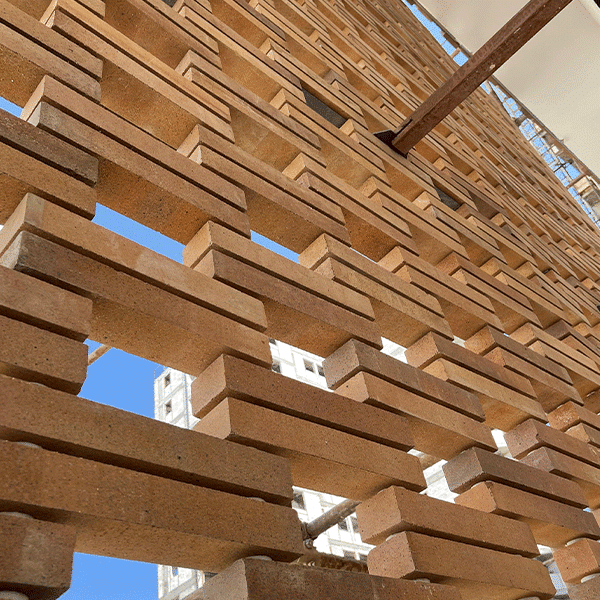

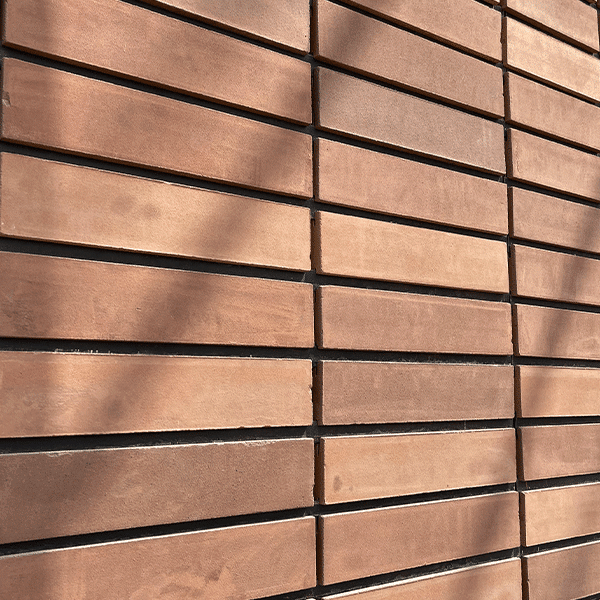

Dry facade brick is an integrated system of a series of bricks with a specific geometric shape fixed on a series of metal rails. With this type of brick, it is possible to stack and dismantle the brick repeatedly without damage. Also, do not use sand and cement mortar and any glue in brick installation. It makes it possible to use any type of insulation behind the brick facade. It creates a watertight appearance against wind and water and allows it to be used on any type of structure or wall.

The components of Jourchin's dry brick facade using the rail method

Façade support structure

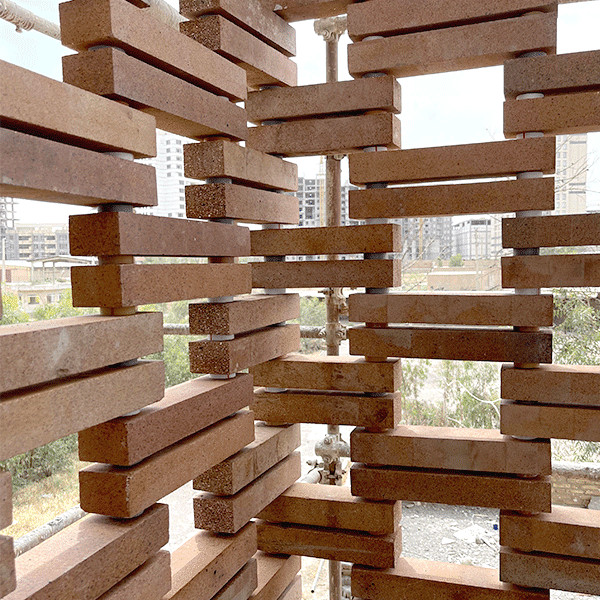

The supporting structure of the facade shell has the task of bearing the load of the facade and connecting the shell to the building structure, which is of particular importance in all methods of dry facade implementation. This shell is usually made of steel profiles that are welded or bolted together and should be connected to it according to the type of the main structure of the building. If the skeleton of the building is concrete, using predetermined plates or executed plates and handles attached to it, the facade support structure will be connected to the main structure of the building. In the next stage, horizontal profiles are implemented as belts to place the vertical profiles in the same line, at the level of each floor, and in the last stage, to implement the dry brick facade of Jurchin, the rail method is needed, so that the vertical profiles of the structure supporting the facade with intervals of 60 Centimeters from each other should be installed so that the necessary substrate for the installation of the mentioned connections is realized.

Jourchin dry brick retaining connections

Dry brick facade retaining connections with the rail method designed and produced by Jurchin Company. These rails have different types according to their position, which include lower, middle, upper rails and special connections for rails. Also, special connections are designed and produced for special cases, such as window covers, facade corners, etc. Brick holding rails and joints are made of galvanized sheets with different thicknesses according to its application, which have high resistance. In addition, after production, they are dyed by electrostatic powder paints in furnace method. As a result, the rails produced for use in the facade of the building, which is in front of the atmospheric factors, have very high resistance, stability and longevity. Also, he used painted rails in the part of the band between the bricks as banding between the bricks, which can be changed according to the color chosen for banding at the customer's request. Also, rubber profiles are placed behind the brick holding joints, whose task is to prevent the bricks from being hit. The joints and galvanized rails of Jurchin company are connected to the facade support structure by screws and special joints according to the dimensions and arrangement of the bricks with certain intervals. Rails are connected together with intermediary parts that can easily fix the contraction and expansion and avoid the injuries caused by this process. Also, due to the ability to implement different types of arrangements, Etisalat bricks have the ability to change, which is the project-oriented approach of this method, which can be easily done.

Refractory brick for dry installation

The brick that we use as the final covering has specific physical characteristics and will have its own shape details. According to the investigations carried out on the types of bricks, the best option that has high resistance to breaking and low water absorption are refractory bricks. To install the bricks on the rails, grooves are made on the top and bottom of the brick, which is the location of the dry connection of the brick. The depth of the grooves is different according to the arrangement plan. To install the brick in the facade, it is necessary to first place the top groove of the brick in the rail and then move the brick slightly upwards so that the bottom groove is also placed in the rail. For the implementation of bricks in this method, you do not need to place the bricks in a rail and one after the other, and it is possible to arrange and dismantle each brick separately without the need to destroy or dismantle the side bricks. In order to prevent the earthquake forces on the brick pieces, impact rubbers that are resistant to different climatic conditions are installed at the junction of the brick with the rails, which will reduce the pressure on the brick and prevent it from breaking. The rail is fixed in place.

How to install Jourchin dry brick

The possibility of stacking and dismantling each brick alone without the need to destroy or dismantle the side bricks

The structure of this complex is designed in such a way that, while being firmly connected to the building, it will resist earthquakes completely separately, and the shell will absorb the movements caused by the earthquake in an integrated manner.