One of the most important things for the builder and residents of a building is its safety. If we want to go back to the past, we can say that the mortar or grouting method was the common method of implementing the facade of the building, which has its own advantages and disadvantages; In this era, with the introduction of a new and modern implementation method in the form of dry facade installation with various materials, which due to the high safety of this type of facade, has a great advantage over other facade implementation methods. Dry facade is the first choice of many people.

A part of the building that attracts a lot of attention is its facade, and in this regard, it is very important to implement a high-performance engineering facade that gives a lot of added value to the building. Due to the use of sand, cement and water mortar, the weight of the facade increases and a lot of load enters the building. In order to control this load and reduce it, using the dry facade implementation method, which is very practical in this regard, using modern technology and systems. In the following, we intend to examine it.

Superior and different thinking

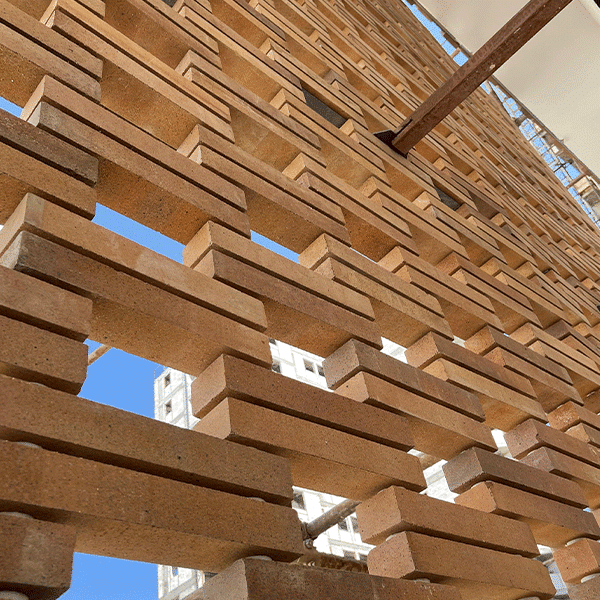

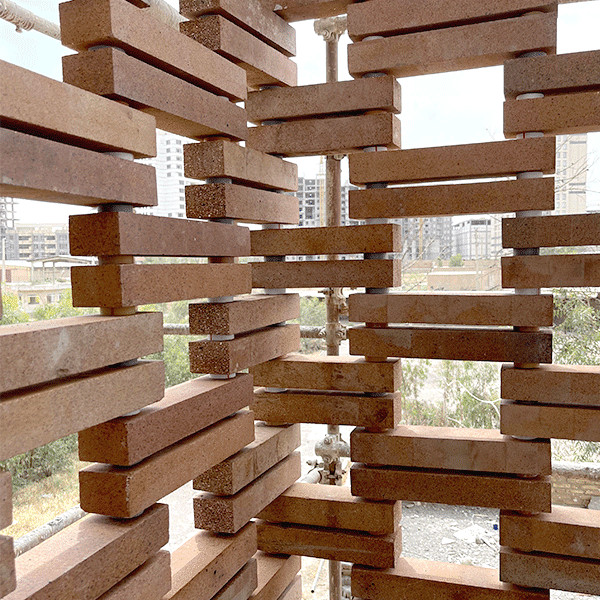

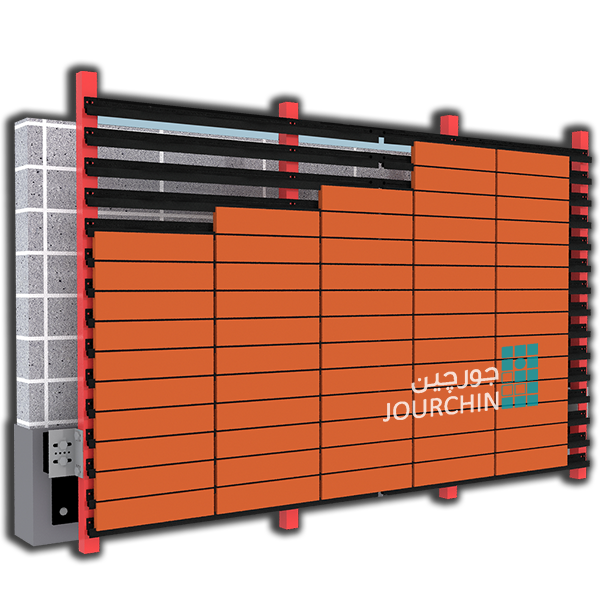

In this method, by using the facade support structure that is responsible for bearing the load and connecting the shell to the building structure, as well as special connections that are responsible for holding the bricks, a unified shell with high resistance is created. The structure of this complex is designed in such a way that, while being firmly connected with the skeleton of the building, it will resist earthquakes in a completely separate way, and the shell will absorb the movements caused by the earthquake in an integrated manner.

Unique design

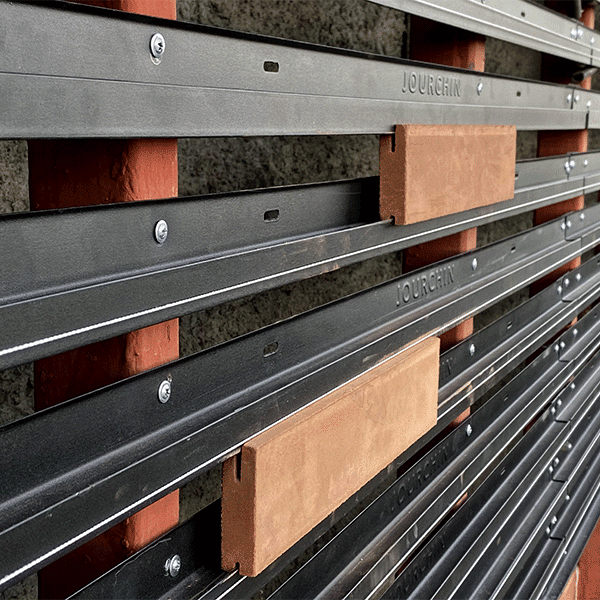

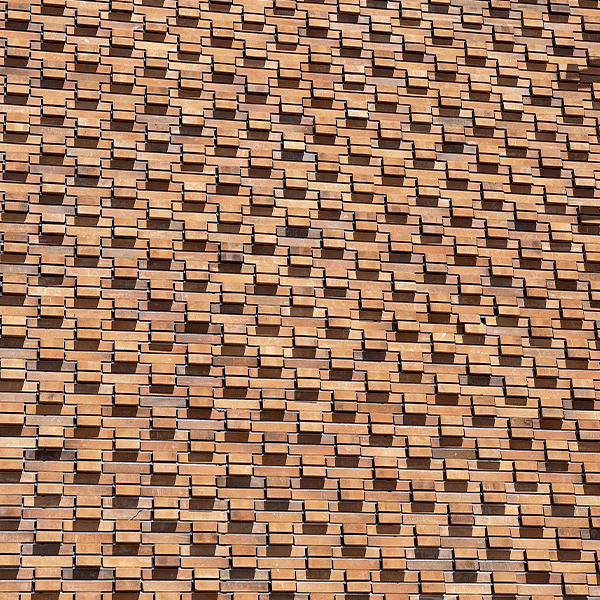

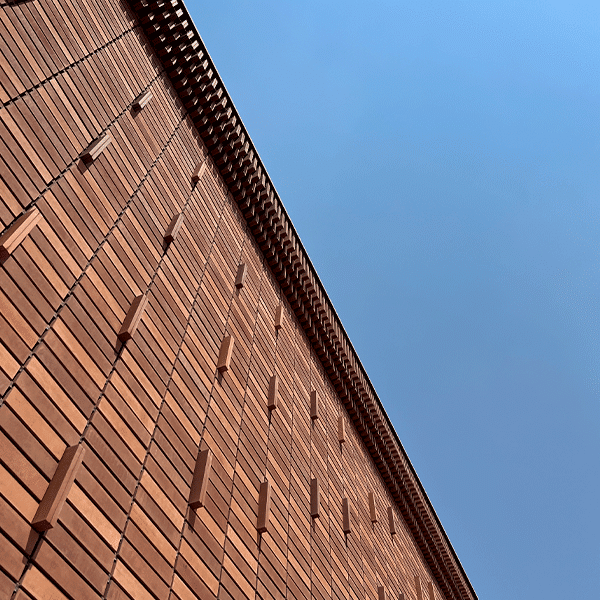

Jourchin company has the honor of combining the valuable experiences of past architects with modern technology and providing the possibility of dry brick execution. The design and implementation method is completely project-oriented and any type of architectural structure with different layouts and dimensions of bricks, considering that the facade of the building is exposed to atmospheric factors, the dry facade is resistant to these factors. It also has the necessary beauty and is in harmony with the facade of the nearby buildings, it is designed and implemented by the experienced engineers of this company. In this method, while simplifying the implementation method, most of the disadvantages of using bricks in the form of mortar have been eliminated.

High integrity and resistance

In this method, by using the facade support structure that is responsible for bearing the load and connecting the shell to the building structure, as well as special joints that are responsible for holding the bricks, a unified shell with high resistance is created. The structure of this complex is designed in such a way that, while being firmly connected with the skeleton of the building, it will resist earthquakes in a completely separate way, and the shell will absorb the movements caused by the earthquake in an integrated way.

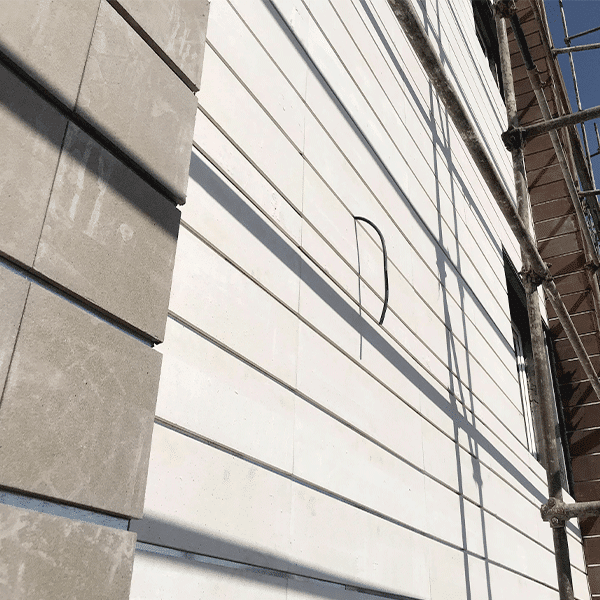

Dry facade refers to modern building facades, in which, instead of using mortar, grout, or any glue, special connections designed for various facade materials are used. This method is much faster, lighter and safer than the mortar method, especially for use in high-rise buildings. Nowadays, the dry facade construction has many fans due to its engineering construction and its advantages, and it is the most popular facade construction method.

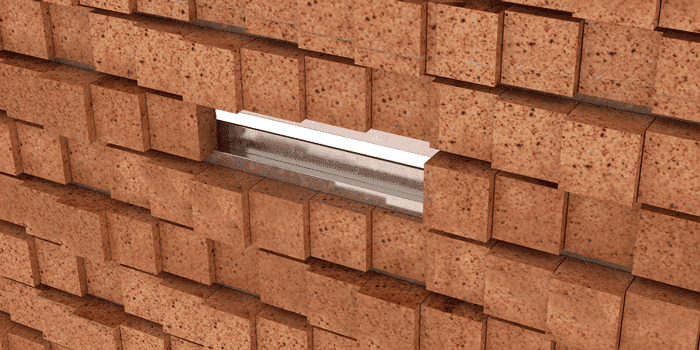

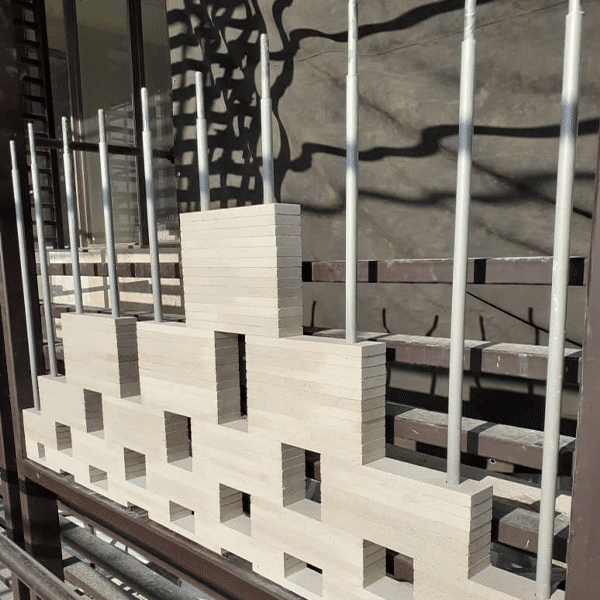

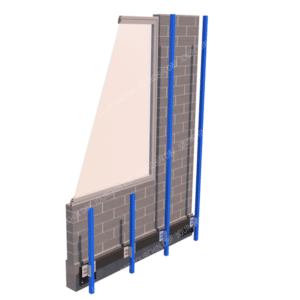

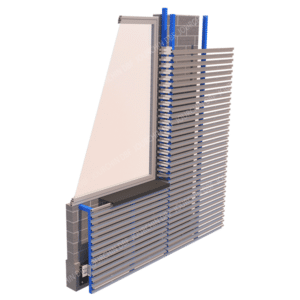

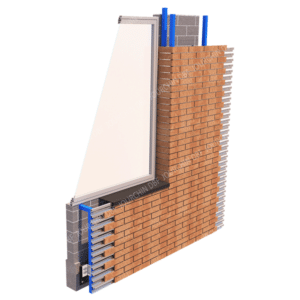

Components of Jourchin dry brick facade

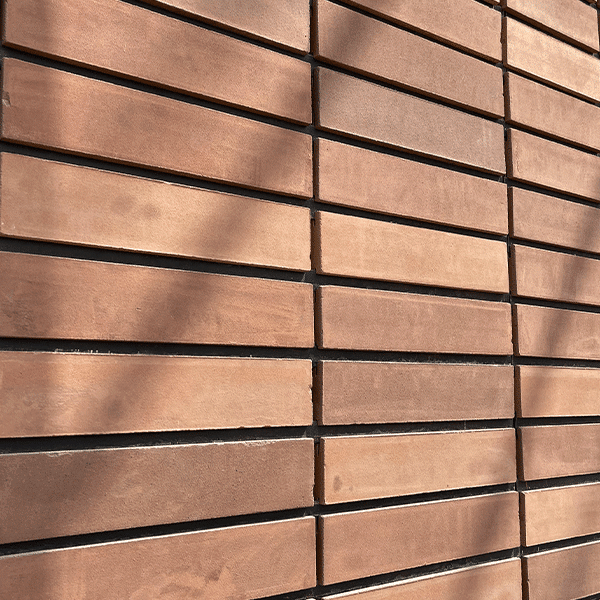

The constituent parts of Jourchin's dry brick facade, which you can see in the opposite picture, consist of the following layers:

1- The supporting structure of the shell

2-Jourchin dry brick retaining connections

3- Refractory brick for dry installation

The reason for the popularity of Jourchin dry brick facade

In the execution of the facade in a dry manner due to the lack of use of mortar; Grout or glue and joining of all facade components with its specific connections, as a result, there is no possibility of the facade components being disassembled, destroyed, or falling after a long period of time. Also, this type of facade implementation has a lot of weight reduction, in this regard, much less load will enter the building, and also because of the engineering design and calculations specific to existing regulations regarding the implementation of dry facades and the construction of the facade with attention to details. It is designed to be highly resistant to the stresses caused by earthquakes.

On the other hand, with the advancements in technology and the spread of modernity, new materials have been produced and put on the market, which cannot be implemented with traditional and mortar methods, and in the dry facade implementation method, various types of materials can be implemented. For example, we can mention materials such as composite, glass, thermowood, porcelain ceramics with large dimensions.

- Reduction of more than 50% of facade weight

- A significant increase in the execution speed and arrangement of bricks

- Ability to perform in any weather conditions

- Not using any mortar or glue to place the bricks

- The possibility of repeated stacking and dismantling of bricks in place without clashing with other rows and destroying the facade

- Implementation of brickwork on any type of wall and structure with any type of structure

- The possibility of execution on all types of arches and domes

- It is possible to implement any type of insulation system behind the facade

- Tolerating the stresses caused by temperature changes, wind and earthquakes

- Affordable and versatile

- In this system, due to the lack of mortar consumption, there is no sediment in the form of scale

- Unlike the mortar method, it does not consume and avoid water wastage

Why should we choose the dry facade of Jourchin brick?

Increasing facade resistance due to weight reduction and earthquake resistance

Increasing facade resistance due to weight reduction and earthquake resistance

Due to the weight reduction of more than 50% per square meter of the executed facade compared to the mortar method, the load on the building will be greatly reduced. For example, a brick facade with 5 cm of grout or mortar weighs about 140 kg per square meter, and in the dry execution method, the weight of this facade is reduced to about 60 kg per square meter. As a result of a building with 1000 square meters of facade, about 80 tons (80,000 kg) of facade weight is reduced. In this regard, the resistance of the building has increased and will have a great impact on the safety and stability of the facade and the collapse of the facade during an earthquake.

Reducing the weight of the building is directly related to reducing the force of the earthquake on the buildings. In the direction of the notes and special points of the Iran Earthquake Regulations (2800) and other earthquake regulations of the world, the design of the infrastructure of the building and the materials of each facade is based on the principles of standard design and in accordance with the conditions contained in the Iranian Regulations 2800 and the connection to the main structure of the building. This means that during an earthquake, the movements of the façade and related accessories are carried out separately by changing the lateral location of the structure, and this will prevent the façade from flaking and its parts from falling like a plaster facade, therefore reducing human casualties and other damages caused by It appears to fall.

Increasing the useful life of the facade and the possibility of repairing and recycling the materials

The implementation of dry facades due to the installation by industrial method, both causes the stability of the building and increases its life span (over 50 years) and does not require maintenance. In case of damage due to an accident, there is also the ability to repair, modify and replace the panels. Even after the end of the life of the building, all the infrastructures and facade materials can be reused in another place or recycled, if they are stable, which is a very good saving in costs, and this means that all costs which is done for the implementation of this view, after the end of the construction work, it will be returned in terms of the standard percentage of the depreciation of the materials. If the useful life of grout facades is only about 15 years, and after that, it will need to be restored and repaired, which coincides with the destruction of the facade and its underlying mortar, which, in addition to creating additional costs, requires finding used materials 15 It is the previous year, and if it is found, due to wear and tear of the facade, the replaced facade will not be the same color in one piece.

Increasing the useful life of the facade and the possibility of repairing and recycling the materials

The possibility of implementing any type of insulation and the performance of the facade as a type of insulation

The possibility of implementing any type of insulation and the performance of the facade as a type of insulation

In the dry facade method, due to the presence of the facade support structure and related connections, an empty space is created between the outer surface of the facade and the main body of the building, in which air flows, which itself acts as an insulator and regulates the temperature. Inside the building and preventing energy wastage is effective. Also, according to the location of the building and the weather conditions of the region, appropriate insulation can be implemented.

Increase execution speed

“Time is golden” is a phrase that is heard a lot these days, in such a situation, we should use the most appropriate solutions to save time. The engineering and industrial systems of the facade of the building are designed in such a way that everything is calculated and done far from error and at the right time, and the installation systems are very easy, which minimizes the implementation time. Different work by different teams also saves time.

Increase execution speed

Reducing material waste

Reducing material waste

In dry installation systems, the engineering calculations necessary to predict the heat transfer coefficient and the amount of contraction and expansion of the foundation and facade materials have been estimated, and based on this, the executive details have been designed and there is no possibility of the materials collapsing due to atmospheric changes. But unfortunately, in mortar systems, due to the difference in heat transfer coefficient and the difference in expansion and contraction of mortar and materials, after some time the materials will separate and there is a possibility of falling.

Adaptability of material behavior against atmospheric temperature changes

In dry installation systems, the engineering calculations necessary to predict the heat transfer coefficient and the amount of contraction and expansion of the foundation and facade materials have been estimated, and based on this, the executive details have been designed and there is no possibility of the materials collapsing due to atmospheric changes. But unfortunately, in mortar systems, due to the difference in heat transfer coefficient and the difference in expansion and contraction of mortar and materials, after some time the materials will separate and there is a possibility of falling.

Adaptability of material behavior against atmospheric temperature changes

Ability to adjust

Ability to adjust

Another advantage of dry facades is that you can easily move facade materials and correct possible errors during implementation or even after completion of work. But in mortar installation systems, we see uneven seams that cannot be repaired without destruction

Saving costs

Due to the reduction of material waste, long useful life of the facade, high resistance and no falling of materials due to weather changes and earthquakes, reduction of the volume and weight of the skeleton, the dry execution method has a higher economic efficiency and is valuable.