Parts Produced For Dry Brick Facade

Square Meters Of Dry Brick Facade Has Been Implemented

Employers

Jourchin Company

The Jourchin Company with more than 40 years of experience of its managers in the field of consulting, designing and implementing various industrial projects, hotels and multi-purpose complexes, was established in 2017. This company has targeted the approach of industrial production, facilitating, speeding up implementation, resistance and strength along with beauty by designing and providing new methods of implementation, in the field of dry building facades. The result of the research of the company’s experts is the presentation of the method of dry brick facades, which has been welcomed by architects and builders with its implementation in several projects. Currently, the services of this company are consulting, design, production of connections and implementation of dry facades, and the experts and specialists of this company are ready to provide any advice and technical information in this field. We hope that with the efforts and creativity of young professionals and with the unhesitating support of experienced professors, we can take more effective steps in our construction industry.

Superior and different thinking

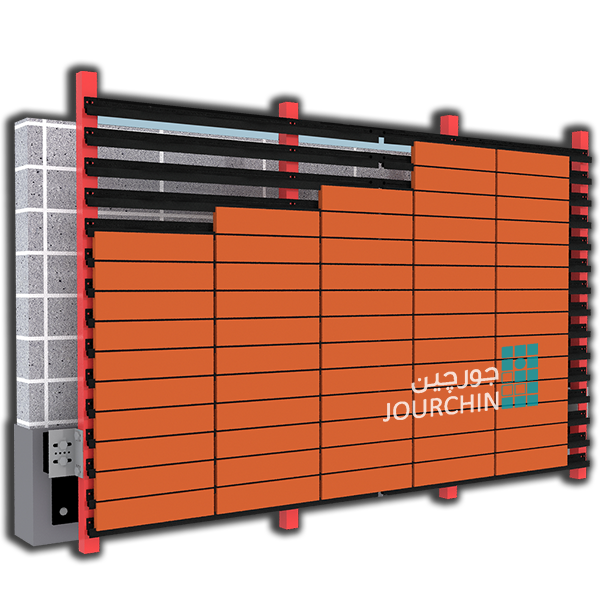

In this method, by using the facade support structure that is responsible for bearing the load and connecting the shell to the building structure, as well as special connections that are responsible for holding the bricks, a unified shell with high resistance is created. The structure of this complex is designed in such a way that, while being firmly connected with the skeleton of the building, it will resist earthquakes in a completely separate way, and the shell will absorb the movements caused by the earthquake in an integrated manner.

Unique design

Jourchin company has the honor of combining the valuable experiences of past architects with modern technology and providing the possibility of dry brick execution. The design and implementation method is completely project-oriented and any type of architectural structure with different layouts and dimensions of bricks, considering that the facade of the building is exposed to atmospheric factors, the dry facade is resistant to these factors. It also has the necessary beauty and is in harmony with the facade of the nearby buildings, it is designed and implemented by the experienced engineers of this company. In this method, while simplifying the implementation method, most of the disadvantages of using bricks in the form of mortar have been eliminated.

High integrity and resistance

In this method, by using the facade support structure that is responsible for bearing the load and connecting the shell to the building structure, as well as special joints that are responsible for holding the bricks, a unified shell with high resistance is created. The structure of this complex is designed in such a way that, while being firmly connected with the skeleton of the building, it will resist earthquakes in a completely separate way, and the shell will absorb the movements caused by the earthquake in an integrated way.

Technical Specifications of Jourchin dry brick facade

in the execution of the facade in a dry manner due to the lack of use of mortar; Grout or glue and conflict of all facade components with its specific connections, which is the result of not being arranged, destruction or falling of facade components after a long period of time. Also, this method of performing the facade has reduced the weight a lot. In this regard, much less load is brought to the building and also due to the engineering design and calculations based on the existing regulations regarding the implementation of dry facades and the construction of the facade according to the designed details, very high resistance to tension. caused by earthquakes.

Visit the dry brick facade projects of Jourchin company.

The reason for the popularity of Jourchin dry brick facade

In the execution of the facade in a dry manner due to the lack of use of mortar; Grout or glue and joining of all facade components with its specific connections, as a result, there is no possibility of the facade components being disassembled, destroyed, or falling after a long period of time. Also, this type of facade implementation has a lot of weight reduction, in this regard, much less load will enter the building, and also because of the engineering design and calculations specific to existing regulations regarding the implementation of dry facades and the construction of the facade with attention to details. It is designed to be highly resistant to the stresses caused by earthquakes.

On the other hand, with the advancements in technology and the spread of modernity, new materials have been produced and put on the market, which cannot be implemented with traditional and mortar methods, and in the dry facade implementation method, various types of materials can be implemented. For example, we can mention materials such as composite, glass, thermowood, porcelain ceramics with large dimensions.